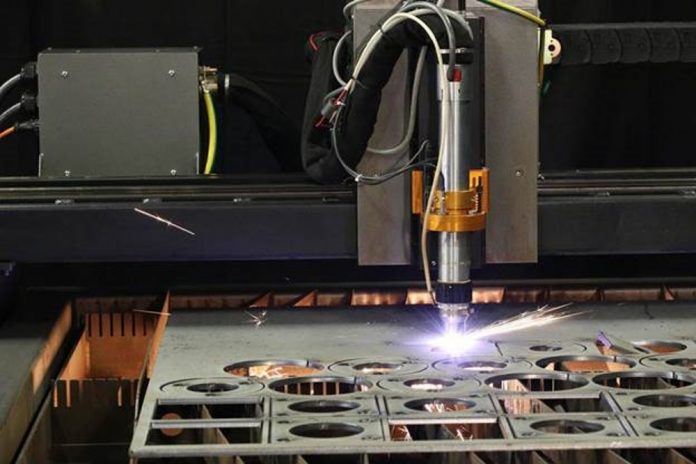

The art of the plasma cutting comes down to the technology. Electricity produces an electric arc and turns the positively charged gas inside the nozzle (of a gas nozzle) toward a consumable (Fahrenheit or Celsius) gas. We use nozzles and consumable in the plasma process.

A plasma cutter works by heating or cutting the plasma. The primary function of the plasma arc is to increase the gas inside the nozzle and thus break it apart. It’s a good mechanical design.

To understand how plasma cutters work with metal, you need to have a basic idea for the process. What happens to a metal plate when something gets hot enough to reach about 200 degrees? And what happens to the metal plate when the plasma cutters shear it? The only way to know is to have been there during the plasma cutting process.

How do plasma cutters cut metal? ORA (Oriented Relays) – are devices used by hundreds of heavy-duty machining centers to apply welds on large surfaces. This device has pins supplying four pass currents, which are arranged in one-to-one or one-to-many correspondences across the back of the contact head.

Consider at least one large contact crosshead, two optional gas line switches, and a fan motor driven by a voltage source. Plasma cutters produce a plasma wave (a combination of electrical pulses), which actually breaks or melts the metal. What happens is when the burning plasma meets the metal plate, the gas is consumed, and the metal plate is cut. There are many more complicated applications – plasma cutters operate for cutting metal, plastics, metal alloys, wood, metal, rubber, flux and plastic, and many others.

Plasma cutters are like welding machines; however, a plasma cutters amperage and voltage determines its size. The welding machine requires relatively low voltage and high amperage levels, whereas the plasma cutter requires high voltage and a low amperage level. Remember that total output power (in watts) equals amperage times voltage, while this is an important indicator.

Read more: 12 Must-Have Welding Tools – A Complete Welding Tools List For Everyone

Because many people erroneously judge a plasma machine solely by amperage; therefore, you need to do the math to obtain a more accurate product comparison. The cutting size of the plasma machine varies based on the manufacturer, you can visit https://assetplant.com.au to learn more about plasma.

What is the standard spectrum model machine cut rating?

- Spectrum 125C

- 12 A @ 110 VDC 3/16 in.

- Spectrum 375

- 27 A @ 90 VDC 3/8 in.

- Spectrum 625

- 40 A 140 VDC 5/8 in.

What are the cutting speed and quality ratings?

For the thickness of metal, the cutting speed allows you to calculate production rates, typically in parts per hour. This will help in making sure that the cutting portion of the operation will not become a bottleneck.

However, there are three standards of cutting:

- Rated cut: it is the thickness of the metal that an operator can easily cut any mild steel at a rate of 10 IPM. A smooth and steady cut is achieved with the best possible cut quality at the minimum speed.

- Quality cut: in this type of cut, the operator can cut thicker material than usual. However, the rate of cutting is slower than the average price. Quality cut’s speed is slower than that of the rated cut, i.e., less than 10 IMP.

- Sever cut: in this state, the operator pushes the material to the maximum thickness capabilities, i.e., 1-1/4 in for a 55-amp unit. However, the cutting speed gets slower than the latter two styles of cut mentioned above, and the cut will require significant clean-up.

The less thick the material, the higher the speed of cutting.

Now you know the fundamental operations of plasma cutting, how it works, and what to expect if you are looking to invest in one.