What is hydrated lime used for? Lime production is one of the oldest types of chemical transformation available. It is a versatile and essential chemical used for construction, metallurgical and environmental applications. It is also used a lot in various industries.

However, two kinds of lime are available: quicklime and hydrated lime. Although both are derived from limestone, they differ in chemical composition and use. While quicklime is made of calcium oxide, hydrated lime is composed of calcium hydroxide.

Quicklime is used to produce aerated concrete blocks, oxygen steel, glass, and organic chemicals. On the other hand, hydrated lime neutralizes industrial wastewater and flue gas treatment.

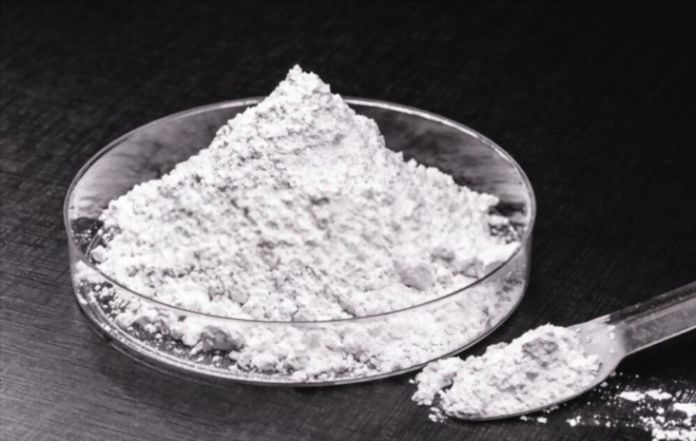

Hydrated lime may also be referred to as calcium hydroxide or slaked lime. It is produced when quicklime is mixed with water. Its chemical formula is Ca(OH)2. It comes either in a white powdery form or as a colorless crystal. You can read more on this here.

Read more: How To Remove Thinset From Concrete.

Properties of Hydrated Lime

Hydrated lime is not very soluble in water. It has a retrograde solubility that increases from 0.66 g/L at a temperature of 100oC to 1.89 g/L when the temperature is 0oC. Hydrated lime will dissolve in pure water at room temperature and produce an alkaline solution whose pH is around 12.5. It is essential to handle it well, as calcium hydroxide solutions can lead to chemical burns.

In the presence of carbon dioxide, an aqueous solution of calcium hydroxide turns milky because of the formation of calcium carbonate. The solubility of this substance decreases drastically at high pH. This is because of a common-ion effect shared with hydroxide anion OH- applicable to cement paste.

Uses of Hydrated Lime

The most extensive single-use of calcium hydroxide is in steel, which removes impurities. Asides from this, it is used in the production of other metals. In construction, it is mainly used for soil stabilization in roads, airfields, earthen dams, and foundations of buildings. It can be used to increase the pH of acidic soil, and this process is referred to as sweetening.

Calcium hydroxide is typically used in producing cement, plasters, mortars, paints, petrochemicals, and complex rubber products. It is also used in tanning leather. Recent uses include environmental applications for removing acid gases in cement mills, coal-fired plants, incinerators, and glassmakers.

Other Uses

Asides from the above uses, hydrated lime is also used in various other ways in agriculture and food production. Due to its mildness and low toxicity, it can be used in livestock and plant production. It is also used to clarify juice from sugar cane and process water for soft drinks and other beverages. Additionally, it is used to fortify fruit drinks and infant formula as a substitute for baking soda and maize preparation.

Calcium hydroxide is used as a flocculant for water and sewage treatment. Forming a soft discharged solid helps remove small particles from the water, making it more transparent. The low toxicity and cost of hydrated lime bring this about.

Furthermore, it is used in the treatment of fresh water. This by raising its pH so that pipes are not corroded in situations where the base water is acidic. Slaked lime is also used to prepare ammonia gas and in paper production. You will find more information on its uses in this article https://www.infoplease.com/encyclopedia/science/chemistry/elements/calcium-hydroxide.

Hydrated Lime Safety Data Sheet (SDS)

Chemicals can be hazardous to health, primarily when not appropriately handled. For this reason, standards are developed to communicate the dangers of different chemicals and how to manage them.

Part of these standards requires that organizations have what is referred to as safety data sheets (SDS). Typically, every chemical has its SDS, and this includes calcium hydroxide. This document summarizes essential safety information about chemicals like hydrated lime.

A hydrated lime SDS easily conveys the chemical and its potential dangers. It includes its properties, safe handling, transportation, storage, precautions, and protective measures. It is important to note that SDSs must have a copy of the document in English, even if other languages are used.

Furthermore, the document must be formatted based on the Global Harmonized System of Classification and Labeling of Chemicals of the UN. This is so that it is easy to search for information quickly. A typical SDS will have the sections below.

- Identification

- Hazard Identification

- Composition of Ingredients

- First-aid measures

- Firefighting measures

- Accidental release measures

- Handling and Storage

- Exposure control and personal protection.

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information

- Disposal considerations

- Transport information

- Regulatory information

- Any other important information

Read more: 6 Common Late-Season AC Repair Needs

Who Needs an SDS, How Do You Obtain It, and Training

An SDS is not intended for use by a general consumer but by workers in an environment where the chemical is used. This means it must be available in laboratories, shops, and other facilities that use the chemical.

Chemical manufacturers and distributors must provide SDSs to downstream users by the Hazard Communication Standard (HCS). Alternatively, you may obtain an SDS from various online sites/databases that provide this information.

All staff must be trained to read, understand and use a partially hydrated lime SDS in the workplace. Different types of training are available, and it is recommended that they be taken annually. Each method should be covered during the training, whether SDS is available; physical, electronic, or both.

Conclusion

Hydrated lime is an important chemical that is useful in many applications. Like every other chemical, it can be hazardous if not handled appropriately. Therefore, it requires an SDS. The SDS must always be available, and every employee must be trained to read and understand it.